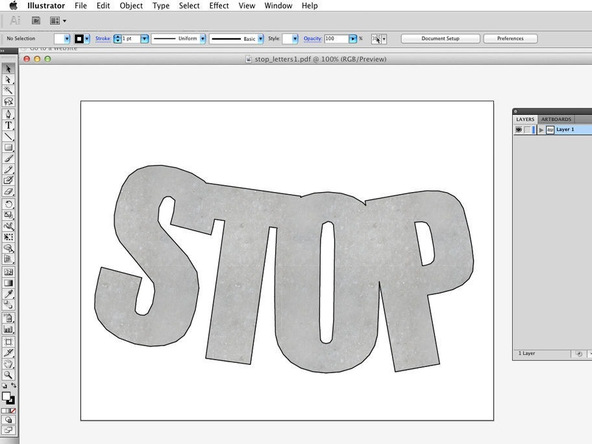

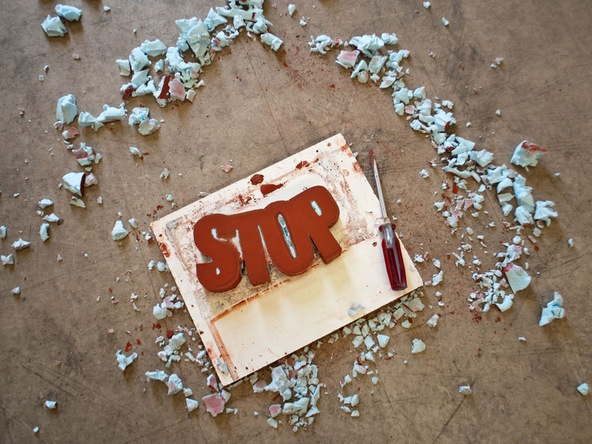

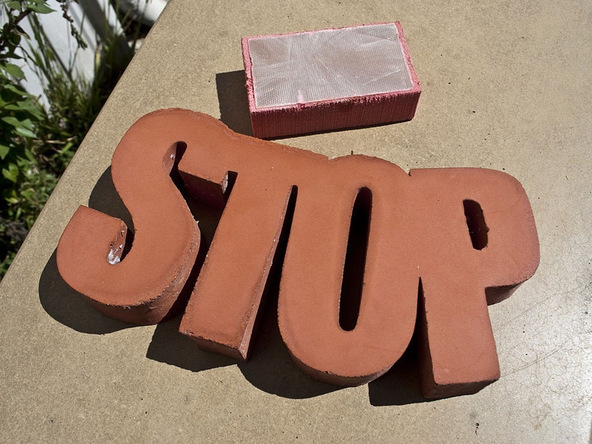

This Guide will show you how to make a concrete door stop using a piece of 2″-thick insulating foam. This project is easy to do with scrap materials. First, print out a template, then trace it onto foam and cut out the void in the foam. Glue it down to a baseboard and fill it with concrete. This simple technique has a wide range of possibilities.

What You’ll Need

- Jigsaw

- Mixing Bucket

- Trowel

- Particle Mask

- Rubber Gloves

- Diamond Hand Sanding Pad

What You’ll Need

- Sandpaper (120-, 220-grit)

- Spray Adhesive

- Insulating Foam, 2″ thick

- CHENG Outdoor Pro-Formula

- 5000 psi Concrete Mix