Greenbrae Chair

ONE: FORM DETAILS

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed pulvinar fringilla mi at elementum. Mauris tristique nisi felis, nec commodo velit porta ac. Vestibulum commodo ipsum non enim fringilla luctus. Quisque ullamcorper vitae leo eget gravida. Sed vel vestibulum lectus. Donec elementum convallis enim, sit amet tristique dolor hendrerit quis. Nulla facilisi. Suspendisse a tempus tellus.

What You’ll Need

- Greenbrae Chair Instructional Drawings

Step 1 – Form Details

Step 2 – Form Construction

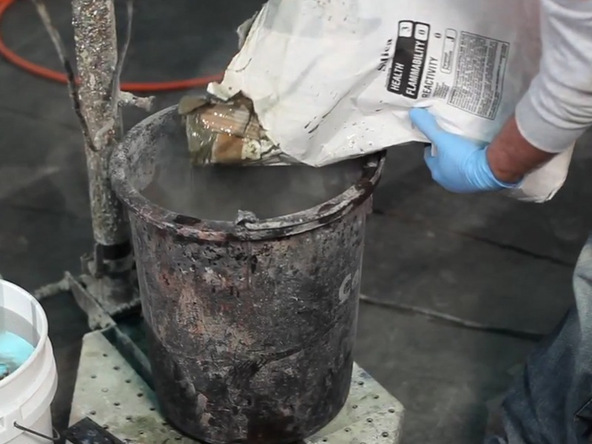

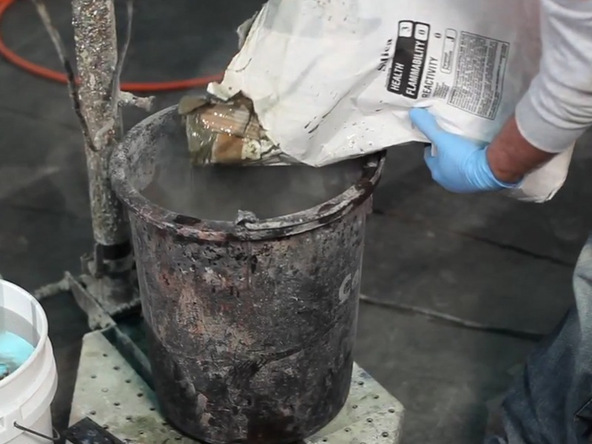

Step 3 – Prepare for Casting

Next: Forming and Mixing

140-163 character description of this project phase. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec enim ante, luctus eu enim vel, eleif luctus eu