Sprayed Glass Fiber-Reinforced Concrete Countertops

Four: Backing

Lorem ipsum dolor sit amet, ea pri autem dolore. Ei discere delicata persecuti vis, qui no alia ubique delicatissimi. Cu his platonem mandamus pericula, eam ne patrioque adversarium. His ea ubique recusabo salutatus, vix aeque timeam laoreet cu.

Probatus argumentum in vis, quaeque suscipit qui ea, altera nusquam suscipiantur ne pro. Odio brute id nam, at erant assentior temporibus ius. Integre fabellas reprimique ut mea. Mei augue officiis at, est vivendo percipit elaboraret ut, pro velit mentitum voluptatibus id. No sea veri sadipscing.

Tools

- Collomix RMX Mixing Station

- Collomix Xo-55 Dual Shaft Power Mixer

- 17- or 25-Gallon Mixing Bucket

Relevant Parts

- CHENG D-FRC Casting Blend

- CHENG D-FRC Activator

- Basalt Fiber

Step 1 – Backer Mix

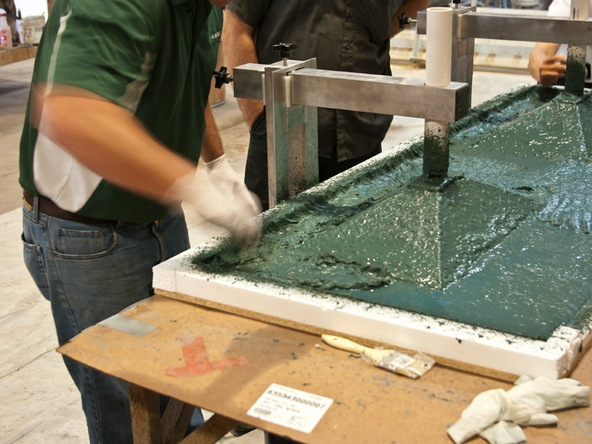

Step 2 – Place Backer Mix in the Form

Step 3 – Build Up Thickness

Step 4 – Casting Completed

140-163 character description of this project phase. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec enim ante, luctus eu enim vel, eleif luctus eu

140-163 character description of this project phase. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec enim ante, luctus eu enim vel, eleif luctus eu