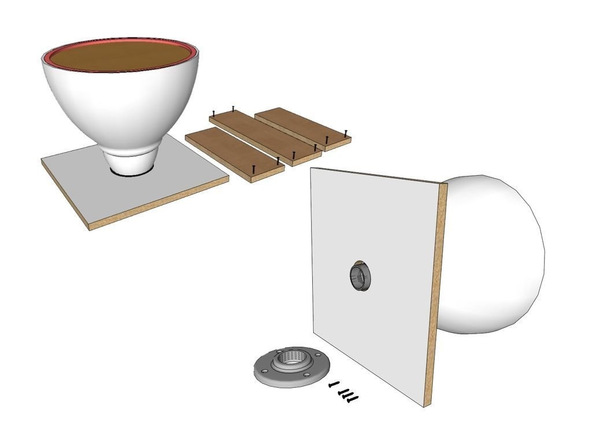

Concrete Umbrella Base

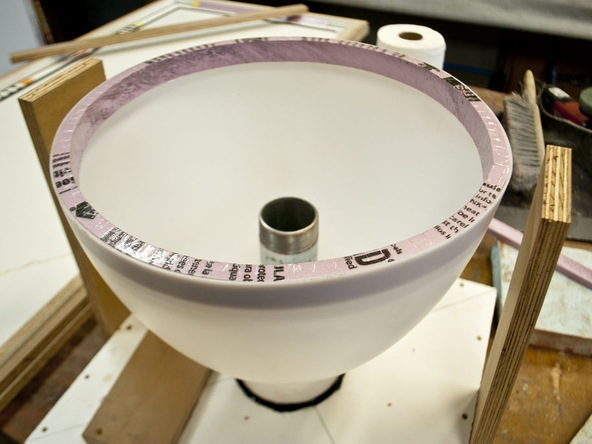

This Guide will show you how to make a concrete umbrella base from an IKEA lampshade using basic tools and materials.

The MELODI lampshade is relatively cheap and makes an attractive concrete mold that can be re-used for dozens of castings. The finished umbrella base is heavy enough to be used with the largest umbrellas, weighing about 100 lbs. There is a smaller version of the MELODI lampshade that can be used for this project, and the finished version will be about half the weight. Because you make this project yourself and choose the size of the pipe that is cast into the concrete, it can be made to work with any umbrella you already own. Furniture pads can be installed under the base to help protect the floor or patio when the piece is moved around.

What You’ll Need

- 2-1/2″ Hole Saw

- Cordless Drill

- Pre-Drill and Countersink Bit

- 1-1/4″ Drywall Screws

- Hacksaw or Angle Grinder

- Alpha VSP-120 Concrete Polisher

- Rubber Gloves

- Dust Mask

- Concrete Mixer

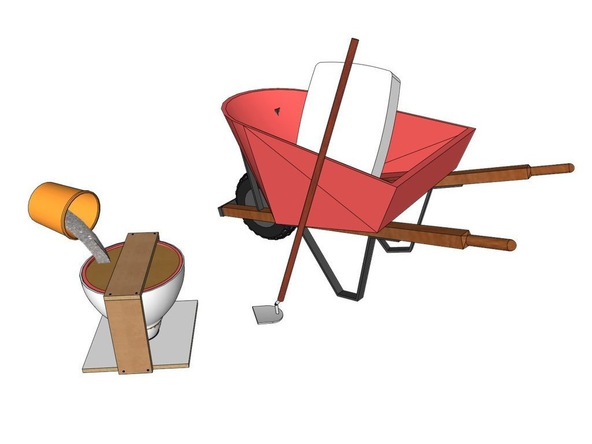

- Wheelbarrow

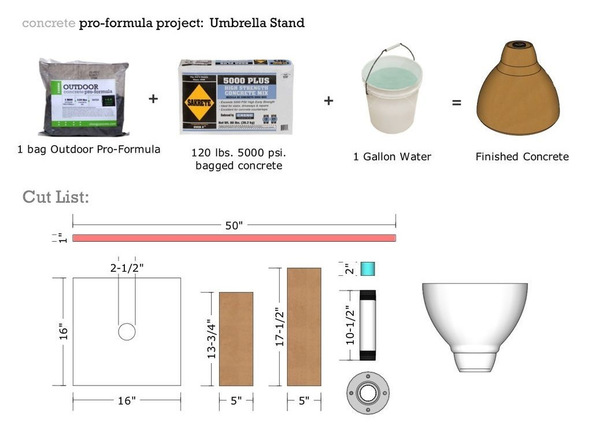

- CHENG Outdoor Pro-Formula

- 100+ lbs. 5000 psi Concrete Mix

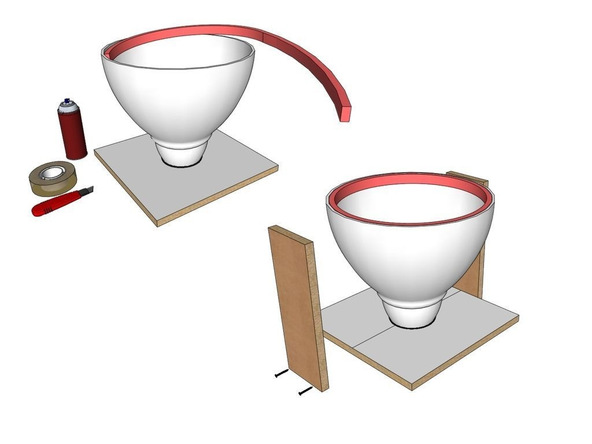

- IKEA MELODI Lampshade

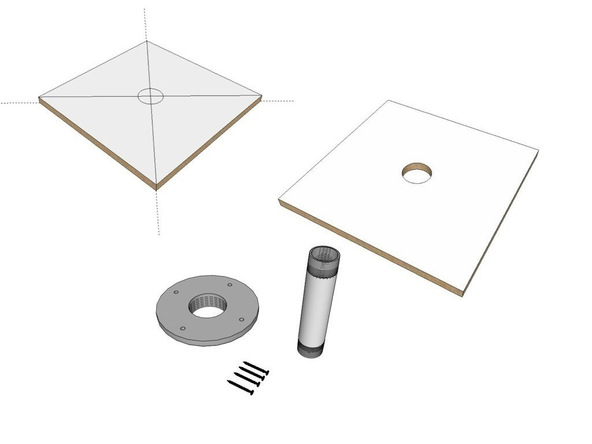

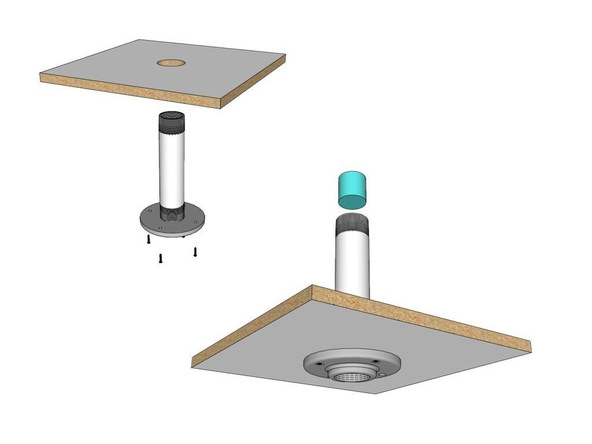

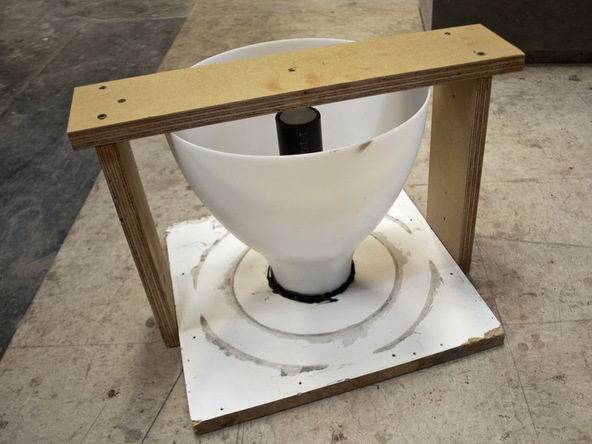

- 3/4″ Plywood Baseboard (16″ x 16″)

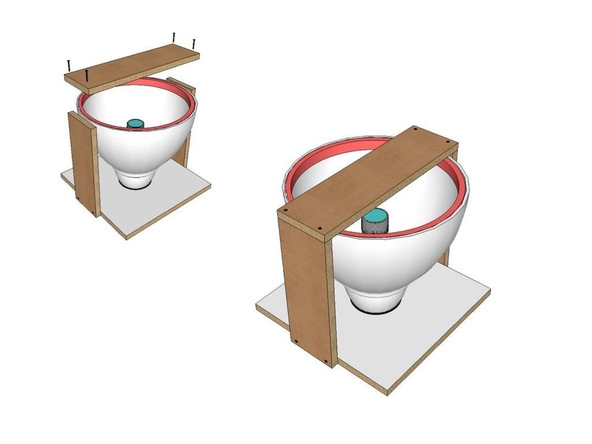

- 2″ Galvanized Pipe with Floor Flange or PVC Pipe

- 100% Door and Window Silicone Caulk

- Modeling Clay

- 1″ x 3/4″ Foam Strip, 50″ long

- Clear Packing Tape