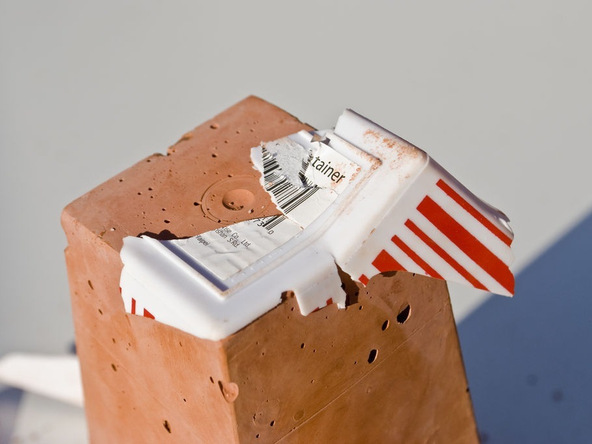

This Guide will demonstrate how to make a concrete iPad stand from a plastic popcorn bucket, inspired by a project from the Easy Concrete Projects book. No previous experience working with concrete is necessary, but you should be comfortable cutting thin plastic with a hand saw, shaping styrofoam, mixing and pouring concrete, cutting away the plastic form, sanding the base, and making the shelf that supports the device from wood or tile.

What You’ll Need

- Ruler

- Permanent Marker

- Clear Packing Tape

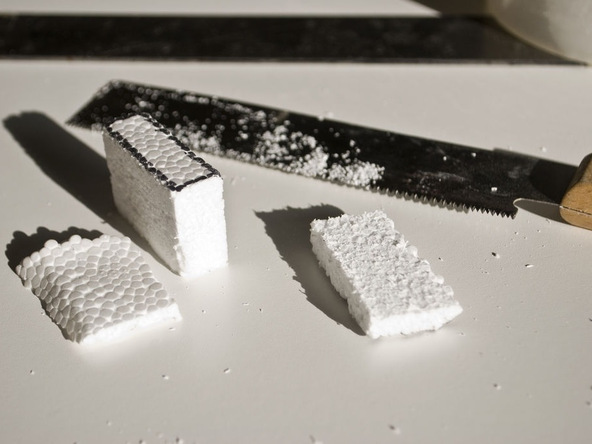

- Hand Saw

- Razor Blades

- Diamond Hand Sanding Pad

- Slotted Screwdriver

- Phillips Screwdriver

- 1/16″ Drill Bit

- 100% Door and Window Silicone Caulk

What You’ll Need

- Rubber Gloves

- Mixing Bucket

- Plastic Putty Knife

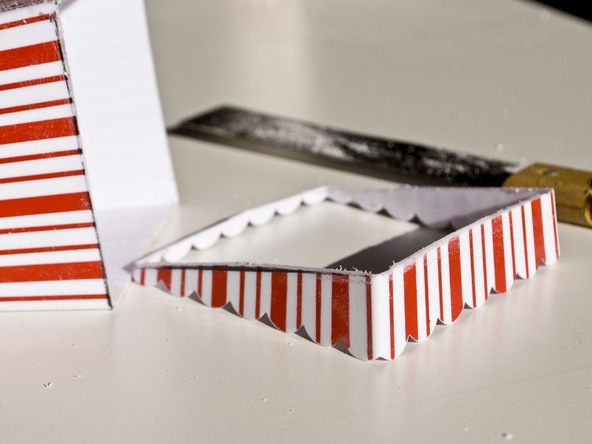

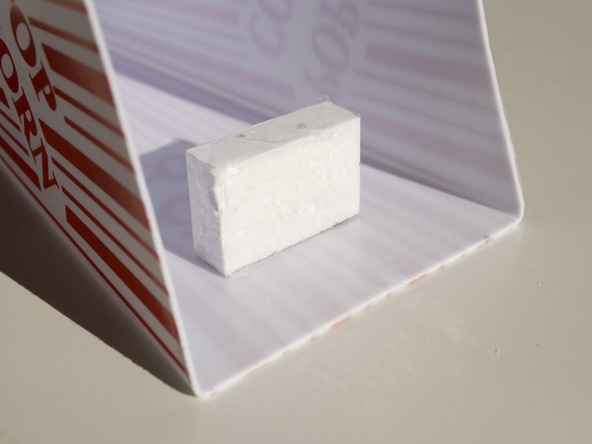

- Plastic Popcorn Form

- Sacked Concrete Mix

- CHENG Pro-Formula Countertop Mix

- Styrofoam

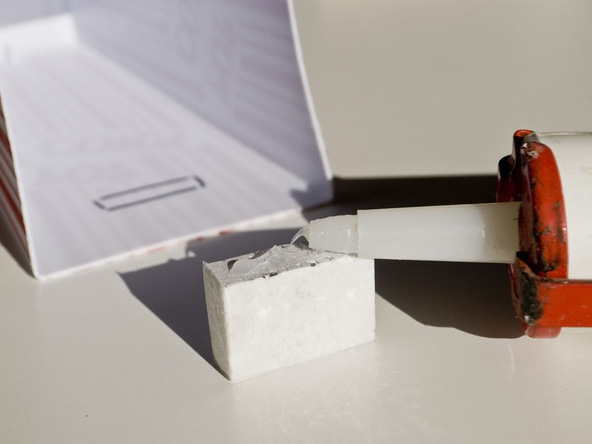

- 2-Part Epoxy

- CHENG Concrete Countertop Sealer

- Wood