Hand-Pressed Concrete Storage Stool

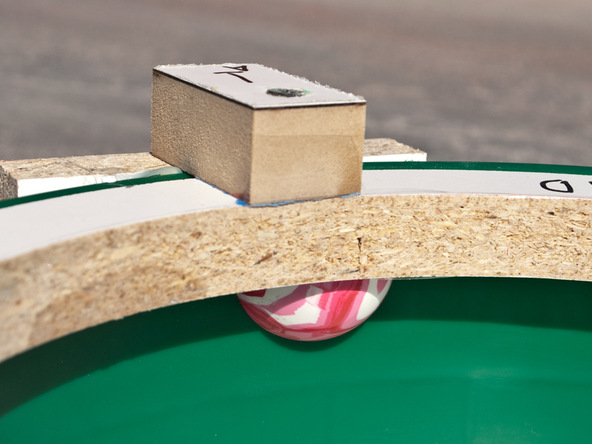

This project uses a 5-gallon bucket to make a two-part stool with lid. It’s a relatively easy project to complete, requiring only basic hand tools and inexpensive forming materials. The result is a versatile side table, storage container, stool, or planter that works indoors or out. Add decorative aggregate to the lid and polish the top for a unique look. Most of the form can be cleaned up and re-used, so it’s possible to make a set without wasting a lot of material.

What You’ll Need

- Jig Saw

- Paddle Mixer

- Ruler

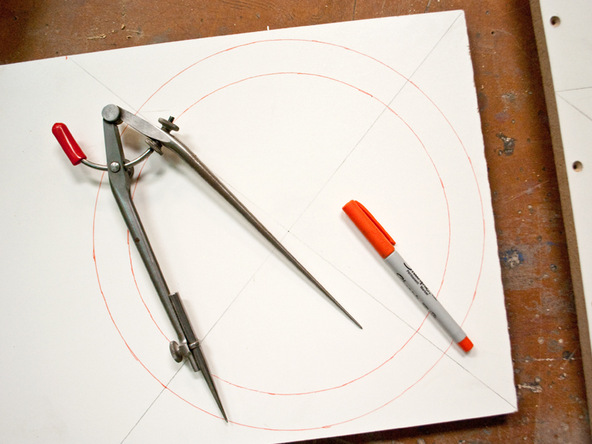

- Compass

- Drill Bit

- Cordless Drill

- 100% Door and Window Silicone Caulk

- CHENG Corner and Seam Shaping Tools

What You’ll Need

- Caulking Gun

- Hand Saw

- Clear Packing Tape

- Denatured Alcohol

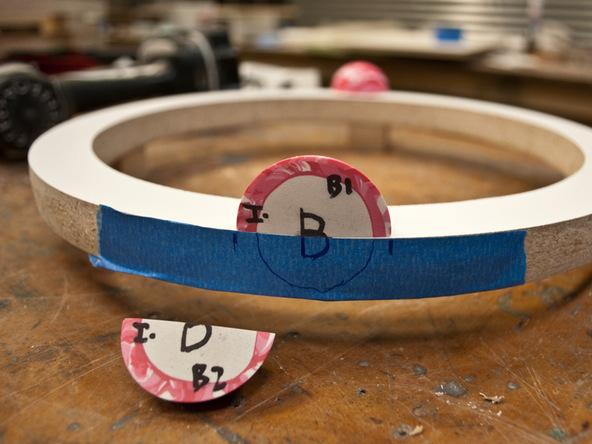

- 3/4″ Melamine

- 5-Gallon Buckets (2)

- CHENG D-FRC Casting Blend

- CHENG SmartColor Pigment

- CHENG D-FRC Activator