How to Burnish Concrete

Learning how to burnish concrete countertops is useful for handling many different problems that might crop up during a project. We like to think of burnishing pads as the “Duct Tape” of our trade because there are so many uses for these pads.

Here are just a few examples of how we use concrete burnishing pads:

- Removing Efflorescence

- Removing Surface Imperfections

- Restoring the Countertop

- Smooth the Sealer

- Remove Wax

What You’ll Need

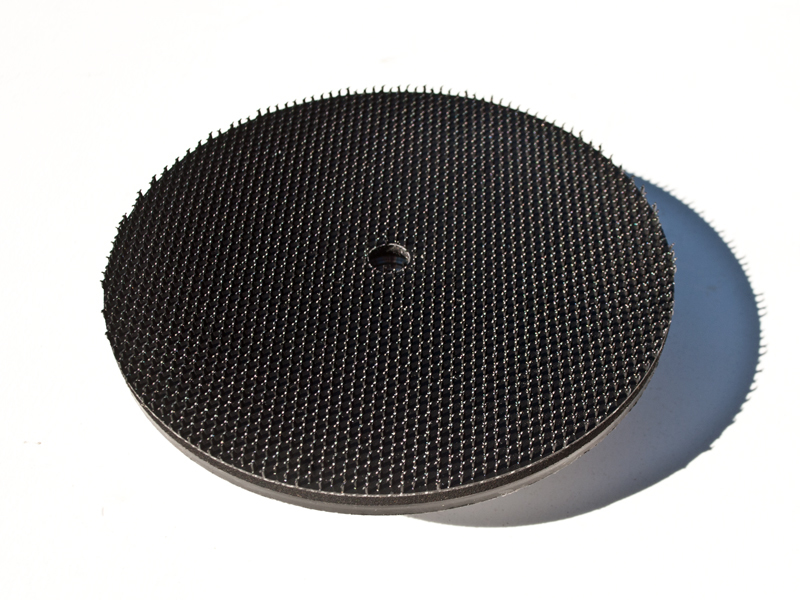

Step 1 – Burnishing Pad Holder

Step 2 – Burnishing Pad Set

Step 3 – Burnishing

How To Identify High Quality Concrete Burnishing Pads:

High quality burnishing pads are manufactured with diamond dust throughout the entire pad. This is achieved by spraying diamond-rich resin directly onto the fibers before the pads are compressed. This method insures equal distribution of cutting power throughout the entire pad.

Low quality burnishing pads are manufactured by taking normal floor scrubbing pads and painting diamond saturated resins onto to one side of the pad. This methods leaves only a thin surface of the pad with cutting power. Once the painted surface is worn off the rest of the pad is useless.