How to Modify A

Power Tex Spray Nozzle

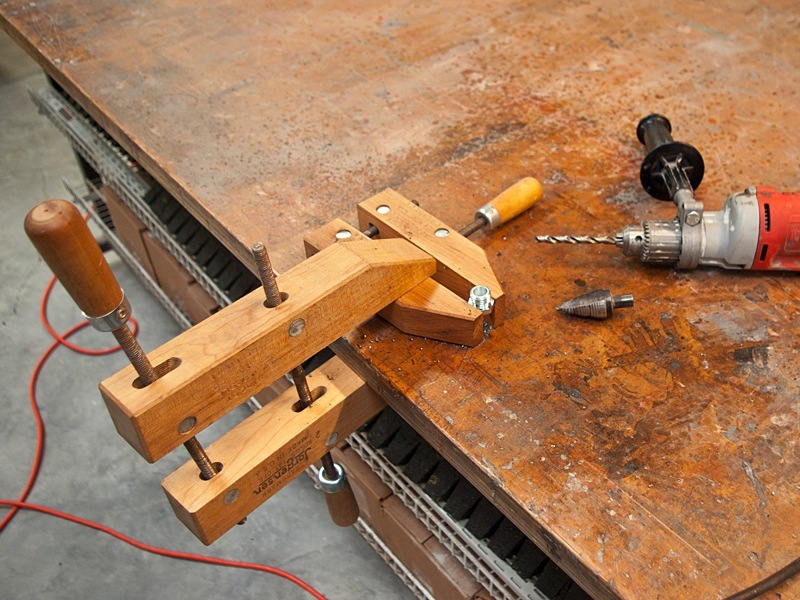

The Power Tex Hopper Gun is sold with a set of 5mm and 7mm spray nozzles of which we only use the 7mm to spray face coat mixes. We bore the 5mm to 5/16″ and it to spray fiber reinforced concrete mixes. This technique is ideal for spraying CHENG’s D-FRC Casting Mix or Surecrete’s Xtreme Precast Mix. The fine PVA fibers in both of these mixes will pass through the larger nozzle with no problems but mixes containing Alkali Resistant Class Fiber shouldn’t be attempted. They will plug the nozzle.

Step 1 – Nozzle Comparison and Setup

Step 2 – Drill 5/16″ Hole

Step 3 – Taper the Back Side

Step 4 – Modification Complete