Rhomba Concrete Bench

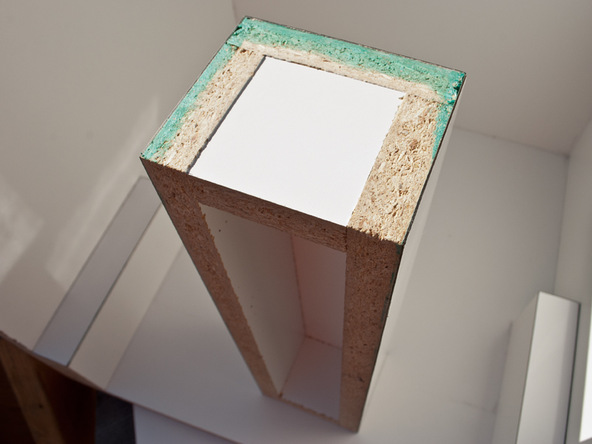

ONE: FORMING

Use high quality materials when building this form to insure the form can be reused for multiple castings. The form constructed for this how-to guide was used to cast more than twenty Rhomba Bench Cubes. Take precautions to avoid scratching or chipping the form pieces when demolding the cubes to maintain a high quality finish on each casting.

What You’ll Need

- Cordless Drill

- Pre-Drill and Countersink Bit

- Corner and Seam-Shaping Tools

- 100% Silicone Calk

- Razor Blades

- Chip Brush

- GFRC Rhomba Bench How-To Drawings

- 3/4″ Melamine

- Contact Adhesive

- Laminate

- Drywall Screws

Step 1 – Construct the Form

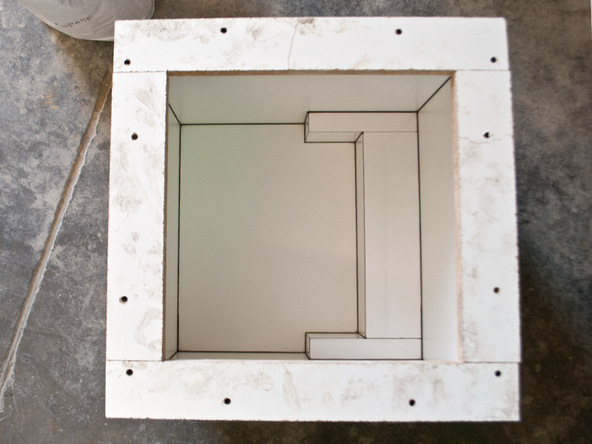

Step 2 – Glue Up the Knockouts

Step 3 – Secure Knockout

Step 4 – Seal the Form

Next: Casting

We prefer to hand place the fiber reinforced concrete mixture onto horizontal surfaces and allow a few minutes for the recently placed…