How to Make a Bent Concrete Table

Our most popular how-to guide walks you through the entire process of making a flexible rubber mold and using it to shape fiber reinforced concrete into a fantastic bent concrete table. The four legs are created as the mold is bent upward while the concrete is still “plastic”, creating four graceful arches that give this table a timeless sense of style.

Project Difficulty

One: Make Master Mold

This project begins with a 3/4″ thick mold made of melamine coated particle board which will be encased in polyurethane mold rubber to create a flexible mold.

Learn MoreTwo: Mix Rubber

Polytek 75-60 Polyurethane Mold Rubber provided ideal flexibility for this project. Work quickly when mixing polyurethane mold rubber to avoid…

Learn MoreThree: Cast Rubber Mold

Polyurethane mold rubber is essentially glue and will stick to most materials, so make sure that all surfaces are protected with Pol-Ease Mold Release.

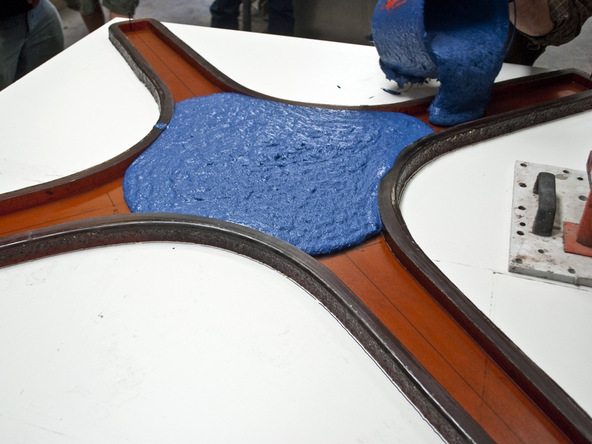

Learn MoreFour: Cast Concrete

To successfully cast this table you need to bend the concrete when it’s at the optimal “plastic” state. If you attempt to bend the concrete too early and…

Learn MoreFive: Demolding

Wait 24 hours before attempting to demold this project. The legs will continue to be delicate until the concrete has reached full strength in seven days.

Learn MoreSix: Sealing

Our favorite sealer for projects shaped like this is the CHENG Hybrid Sealer. The sealer allows us to slowly saturate the concrete with penetrating acrylic.

Learn More