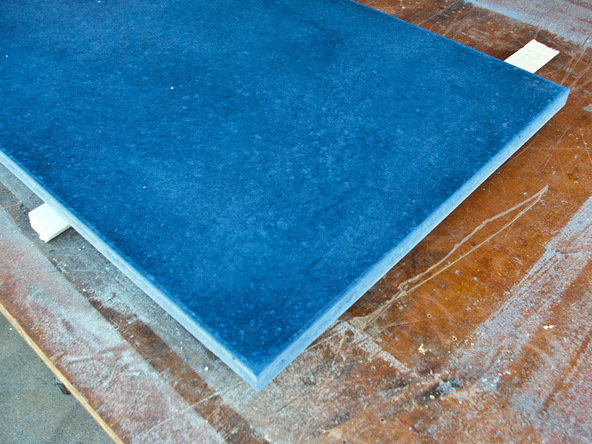

Recycled Glass Countertops

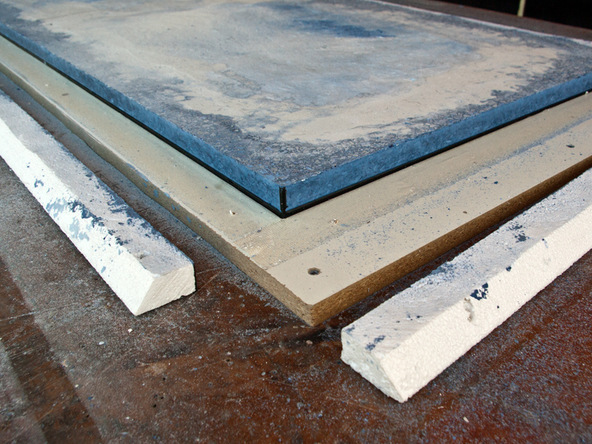

FIVE: GRINDING AND DEMOLDING

Before un-forming, we use a grinder to remove any areas of concrete that might be too high or that have run over the edges of our form.

This is also an ideal opportunity to grind the front bottom edge, making it straight and consistent. It is much easier to shape the underside of the recycled glass countertop before un-molding.

Don’t be deceived by how straightforward demolding this recycled glass countertop is. The majority of all cracking or breaking will occur at this step if proper precautions are not taken to protect the countertop from damage.

Once the countertop is removed from it’s mold, it must always be supported every 12 inches to insure cracks don’t develop.

Step 1 – Grind Bottom of Countertop

Step 2 – Mark Location of Supports

Step 3 – Remove Form Walls

Step 4 – Roll Over

The same vibrating methods are used to precast recycled glass countertops and traditional concrete countertops. This guide uses two Vibco US450T vibrators.

For this project we chose to use a single head wet/dry polisher, but if this project were any bigger, we’d have used a triple-head planetary polisher.