When performance and appearance both matter, the Westcoat 11-10 Custom System delivers.

We’re proud to offer this complete system at Concrete Exchange, where it remains one of our top recommendations for contractors seeking dependable bonding strength, chemical resistance, and unlimited design flexibility. With the full range of components in stock, we help contractors achieve lasting results on patios, walkways, driveways, and pool decks — combining the technical performance concrete surfaces demand with the customized look clients expect.

What is the Westcoat 11-10 Custom System?

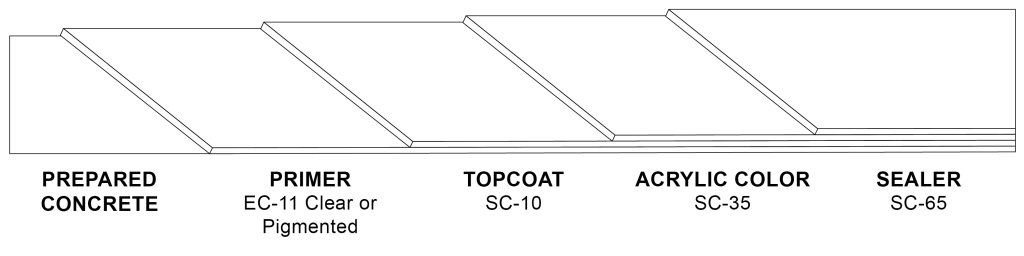

The 11-10 Custom System is a durable, decorative concrete topcoat system that combines multiple proven technologies to protect and beautify exterior surfaces. It consists of four main components:

- EC-11 Water-Based Epoxy Primer — Delivers outstanding penetration and adhesion to prepared concrete.

- SC-10 Acrylic Topcoat — A tough, low-sheen, wear-resistant layer that offers UV protection, chemical resistance, and easy maintenance.

- SC-35 Water-Based Stain — Provides unlimited decorative color options with the ability to create vibrant, variegated, or solid-color finishes.

- SC-65SG Water-Based Semi-Gloss Polyurethane Sealer — Adds chemical resistance, abrasion resistance, and a refined semi-gloss appearance.

- Optional Safe Grip aggregates (CA-29, CA-30, or CA-31) can be incorporated into the system to enhance skid resistance, making it ideal for walkways, driveways, and pool decks.

By combining strength, flexibility, and aesthetics, the 11-10 Custom System delivers a superior surface that stands up to daily use and environmental exposure.

Ideal Applications for the 11-10 Custom System

Westcoat’s 11-10 Custom System is suitable for a wide range of exterior concrete applications, including:

- Patios and outdoor living areas

- Walkways and pedestrian zones

- Driveways and parking surfaces

- Pool decks and recreational areas

It is engineered for surfaces that require both decorative appeal and reliable, long-term performance under foot and vehicular traffic.

Key Benefits of the 11-10 Custom System

Superior Bond Strength — EC-11 Water-Based Epoxy ensures maximum adhesion to properly prepared concrete surfaces.

Durable and Wear-Resistant — SC-10 Acrylic Topcoat creates a tough, low-sheen layer that stands up to abrasion, weathering, and regular maintenance.

Chemical Resistance — The complete system protects against exposure to acids, oils, solvents, and household chemicals.

Customizable Aesthetics — By combining SC-10 Acrylic Topcoat with SC-35 Water-Based Stain, the system offers unlimited color options and decorative techniques for complete creative control.

UV Resistant — Retains color vibrancy and finish integrity even in direct sunlight.

Water-Based System —Low odor, easy maintenance, and VOC-compliant materials built for outdoor performance.

Easy to Maintain — SC-65 Water-Based Semi-Gloss Polyurethane Sealer repels dirt and staining agents, reducing long-term upkeep.

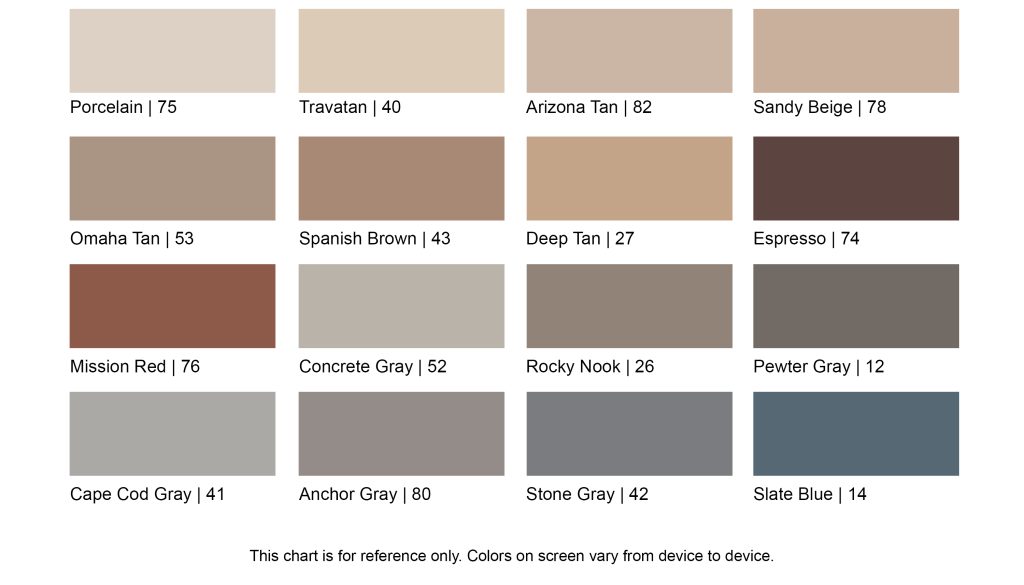

Customize Your Base with SC-10 Stock Colors

The SC-10 Acrylic Topcoat offers a range of durable, UV-resistant colors that serve as the base layer for the 11-10 Custom System. With over 20 stock and made-to-order options, contractors can achieve both traditional and contemporary looks while ensuring excellent color retention and performance.

Highlights of SC-10 Colors:

- Available in popular neutrals, earth tones, and accent shades

- Excellent hide and color retention in exterior conditions

- Low sheen, durable finish designed for foot and vehicular traffic

Add Depth and Creativity with SC-35 Stain Colors

The SC-35 Water-Based Stain offers contractors and installers versatile options for adding decorative effects to exterior concrete surfaces. These stains can be layered, thinned, or applied in creative techniques to achieve everything from subtle variegation to bold, dramatic color.

Highlights of SC-35 Colors:

- Stocked in a curated range of natural earth tones, including grays, browns, and warm neutrals

- No rinsing or neutralizing required — simplifies installation compared to acid stains

- Water-based formulation for easy application, low odor, and quick clean-up

Westcoat 11-10 Custom System Application Overview

Below is a brief summary of the application process for the Westcoat 11-10 Custom System. For complete installation instructions, including detailed preparation, mixing, and application guidelines, please download the full system specification sheet here:

DOWNLOAD FULL 11-10 CUSTOM SYSTEM SPECIFICATION

It is the responsibility of the installer to review and follow all product specifications prior to beginning work.

1. Surface Preparation

- Prepare the substrate to ICRI CSP 3 profile.

- Remove grease, oil, coatings, laitance, and any surface contamination.

- Confirm substrate strength (minimum 2,500 PSI) and cured (28 days minimum).

- Perform moisture testing and address any elevated levels prior to application.

2. Crack and Surface Repair

- Route cracks larger than 1/32” to ¼” x ¼”.

- Fill with EC-72 Epoxy Patch Gel and allow proper curing time before priming.

3. Primer Application — EC-11 Water-Based Epoxy

- Mix two parts A with one part B by volume.

- Thin with water if needed for better concrete penetration.

- Apply at 500–800 ft² per gallon using a ¼” nap roller, avoiding puddling.

- Proceed to SC-10 application within 1–6 hours of primer drying.

4. Base Color Application — SC-10 Acrylic Topcoat

- Thoroughly mix; thin the first coat only if necessary to improve flow.

- Apply one to two thin coats at 200–400 ft² per gallon.

- Cross-roll to achieve a uniform and consistent appearance.

5. Decorative Staining — SC-35 Water-Based Stain

- Apply using a sprayer, broom, or brush.

- For mottled effects, pre-dampen the surface or blend colors during application.

- Coverage rates vary from 400–600 ft² per gallon.

6. Sealer Application — SC-65SG Semi-Gloss Polyurethane Sealer

- Mix three parts A with one part B by volume.

- Apply at 400–650 ft² per gallon via sprayer, roller, or broom.

- Allow minimum cure times of 12 hours for light traffic, 24 hours for standard use, and 72 hours for vehicular or water exposure.

Best Practices for Successful Installations

- Monitor weather conditions. Avoid application before rain (48 hours) or heavy dew (24 hours).

- Control surface moisture. Always confirm slab conditions before coating.

- Maintain a wet edge. Especially critical when applying SC-65SG to avoid visible lap lines.

- Incorporate slip resistance. Add Safe Grip aggregates (CA-29, CA-30, or CA-31) where needed.

- Box batches for consistency. Mix multiple batches of SC-10 or SC-35 together to ensure uniform color throughout the project.

Why Specify the 11-10 Custom System?

The Westcoat 11-10 Custom System offers a durable, decorative solution for exterior concrete surfaces where aesthetics and performance must work together. Its combination of strong adhesion, chemical resistance, and easy maintenance makes it a trusted choice for professionals seeking reliable, long-lasting results without compromising design flexibility.

Ready to upgrade your next project?

Shop the full Westcoat 11-10 Custom System at Concrete Exchange — everything you need for strong, durable, and decorative concrete finishes in one place.

- EC-11 Water-Based Epoxy Primer

- SC-10 Acrylic Topcoat

- SC-35 Water-Based Stain

- SC-65SG Water-Based Semi-Gloss Polyurethane Sealer

- Optional Safe Grip aggregates (CA-29, CA-30, or CA-31) can be incorporated into the system to enhance skid resistance, making it ideal for walkways, drive