Quadra Fire Pit

ONE: FORMING

Video Overview

What You’ll Need

- Jigsaw

- Quadra Fire-Pit How-to Drawings

- Cordless Drill

- Countersink Drill Bit

- Contact Adhesive

- Adhesive Rollers

- 100% Silicone Calk

- Corner & Seam Shaping Tools

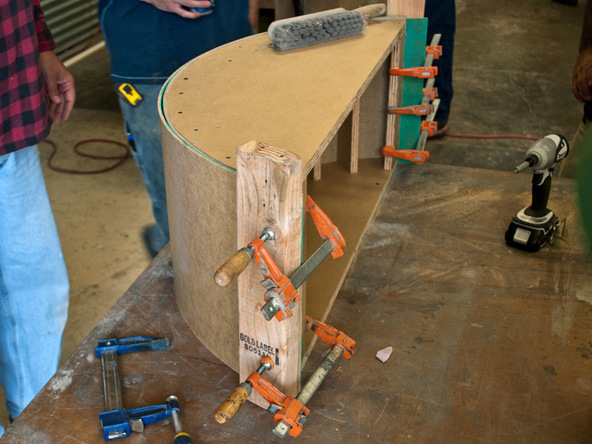

- Bar Clamps

- Drywall Screws

- Lumber

- Power Saw

Step 1 – Create the Knockout

Step 2 – Secure the Masonite Facing

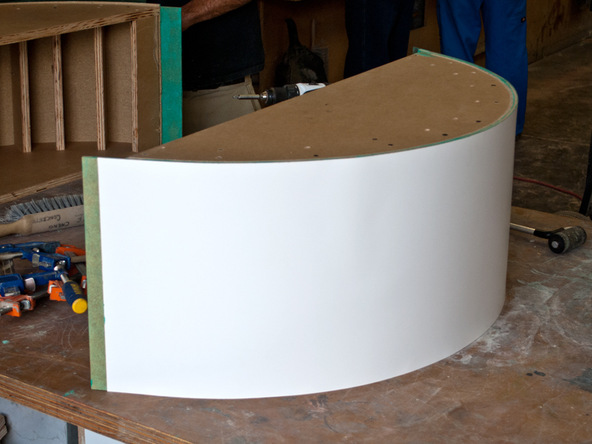

Step 3 – Attach Masonite

Step 4 – Attach Casting Surface

Step 5 – Build a Box

Step 6 – Secure the Knockout

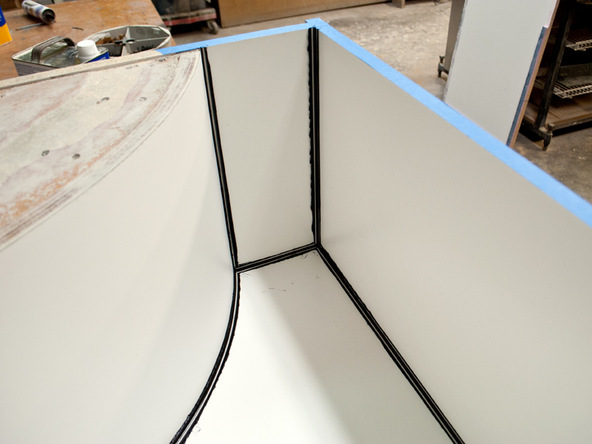

Step 7 – Seal the Form

Next: Casting

The high vertical layups require you to take your time and insure previous layups are firm enough to support the full wall thickness while casting.