Grind, Stain & Seal systems remain one of the most versatile solutions for enhancing existing concrete while maintaining substrate integrity and achieving a high-value decorative finish. Unlike a standard Grind & Seal, this approach incorporates a stain layer, water-based, nano-based, or acetone dye, to deliver color without the handling hazards or neutralization steps associated with acid staining.

This guide provides a detailed comparison of the three major stain technologies used in Westcoat Grind, Stain & Seal installations (SC-35, SC-36, SC-37), along with four industry-proven sealers (SC-65, EC-11, SC-70, SC-42). Each section highlights where the product excels, performance considerations, and pairing recommendations, giving you a clear blueprint for specifying the right system for each environment.

What Is a Grind, Stain, and Seal System?

A Grind, Stain & Seal System is a versatile decorative concrete finishing process that combines mechanical surface preparation with semi-transparent color stains and high-performance sealers. The system enhances existing concrete while maintaining substrate profile, making it ideal for residential interiors, commercial spaces, and decorative exterior environments. It consists of three primary components:

Mechanical Grinding —

Prepares and Opens the Surface

Diamond grinding removes contaminants, exposes a clean substrate, and creates a CSP-2/3 profile to ensure optimal stain penetration and sealer adhesion.

- Typically performed with 60–80 grit diamonds

- Required for all stain chemistries (SC-35, SC-36, SC-37)

- Ensures uniform absorption and predictable color development

Stain Application —

Adds Semi-Transparent Decorative Color

Choose from three stain technologies based on color intensity, dry time, environmental needs, and desired aesthetic:

Each stain type offers blendable colors, multiple application techniques, and the flexibility to create custom, variegated, or layered effects.

Protective Sealer —

Provides Long-Term Performance and Surface Protection

After staining, the concrete is sealed with one of Westcoat’s high-performance clear topcoats. Sealer selection depends on traffic level, UV exposure, gloss preference, and interior/exterior use:

SC-65 Water-Based Polyurethane

Interior/exterior, high-performance durability

EC-11 Water-Based Epoxy

Interior topcoat, exterior primer under UV-stable coatings

SC-70 Acrylic Lacquer

Exterior-only, high-gloss “wet look”

SC-42 Water-Based Acrylic

Interior/exterior, breathable and cost-effective

Optional Slip-Resistance Additives

Safe Grip aggregates (CA-29, CA-30, CA-31) can be incorporated into the final sealer coat to improve traction.

Westcoat’s Grind, Stain & Seal systems provide long-lasting protection, decorative flexibility, and a proven system structure for both interior and exterior applications.

Ideal Applications for a Grind, Stain, and Seal System

Westcoat’s Grind, Stain & Seal System can be adapted for a wide range of interior and exterior concrete installations. Because the system incorporates multiple stain chemistries (SC-35, SC-36, SC-37) and sealer technologies (EC-11, SC-42, SC-65, SC-70), the ideal applications depend on the stain–sealer combination selected.

Residential Interior Floors

Ideal for decorative interiors where low maintenance and modern aesthetics are desired.

Stains: Choose from SC-35, SC-36, SC-37; Sealers: Choose from EC-11, SC-65, SC-42

Commercial & Retail Interior Floors

Durable color and strong protective finishes for high-traffic customer-facing spaces

Stains: Choose from SC-35, SC-36, SC-37; Sealers: Choose from EC-11, SC-65, SC-42

Exterior Patios, Walkways & Outdoor Living Spaces

UV-stable, weather-resistant protection for outdoor entertainment areas

Stains: Choose from SC-35, SC-37; Sealers: Choose from SC-65, SC-42, SC-70

Residential Driveways & Light Vehicular Zones

Long-term protection against tire wear and sun exposure

Stains: SC-35, SC-37; Sealers: Choose from SC-65, SC-42, SC-70

Product Suitability Summary

Interior-Only: SC-36 Fast Stain, EC-11 Sealer (as a finish coat)

Interior/Exterior: SC-35 and SC-37 Stains, SC-42 and SC-65 Sealers

Exterior-Only: SC-70 Sealer

Key Benefits of a Westcoat Grind, Stain, and Seal System

Enhanced Penetration & Adhesion — Mechanical grinding opens the concrete surface for deep stain penetration (SC-35, SC-36, SC-37) and ensures optimal sealer adhesion with EC-11 Epoxy, SC-42 Acrylic, SC-65 Polyurethane, or SC-70 Lacquer.

Durable, Wear-Resistant Protection — When paired with high-performance sealers like SC-65 or SC-42, the system delivers long-lasting abrasion resistance suitable for residential, commercial, and exterior environments.

Fast Turnaround Options — SC-36 Fast Stain allows contractors to achieve vibrant color effects with near-instant dry times; ideal for high-volume commercial work or tight project schedules.

Customizable Decorative Aesthetics — SC-35, SC-36, and SC-37 offer a wide range of semi-transparent color tones, blendable hues, and artistic techniques, enabling effects from subtle washes to bold, variegated, multi-color designs.

UV-Resistant Exterior Performance — When paired with exterior-rated sealers such as SC-42, SC-65, or SC-70, Grind, Stain & Seal systems maintain color integrity and gloss levels even under direct sunlight and weather exposure.

Water-Based, Low-Odor Options — Both SC-35 and SC-37 stains, and sealers like EC-11, SC-42, and SC-65—offer low odor, VOC-compliant solutions suitable for occupied buildings, residential interiors, and environmentally sensitive locations.

Easy, Predictable Maintenance — Protected with high-quality sealers, Grind, Stain & Seal floors resist staining, simplify routine cleaning, and support cost-effective reseal cycles every 3–5 years, depending on traffic and exposure.

Westcoat Stain Comparison: SC-35, SC-36, SC-37

Westcoat SC-35 Water-Based Stain

SC-35 Water-Based Stain provides a low-odor, semi-transparent way to enhance interior or exterior concrete. It produces soft, natural tones and blends easily for layered or variegated effects.

- Semi-transparent, natural earth tones

- Thinnable for softer color effects

- 600–1,000 sq ft/gal coverage

- Interior/exterior compatible

- Works with water- or solvent-based sealers

SC-35 Colors

Westcoat SC-36 Fast Stain (Interior Only)

SC-36 mixes with acetone to penetrate deeply, producing bold tones ideal for commercial interiors, polished concrete, and high-design spaces. Dries in seconds.

- Vibrant, blendable colors

- Ultra-fast drying

- Up to 400 sq ft/gal coverage

- Interior use only

SC-36 Colors

Westcoat SC-37 Nano Stain

SC-37 uses nano technology for deeper penetration and richer color development. Ideal for decorative and light commercial work.

- Nano-sized pigments for enhanced penetration

- Semi-transparent, variegated finish

- 400–800 sq ft/gal coverage

- Interior/exterior

- Blendable for custom colors

SC-37 Colors

Westcoat Sealer Comparison: SC-65, EC-11, SC-70, SC-42

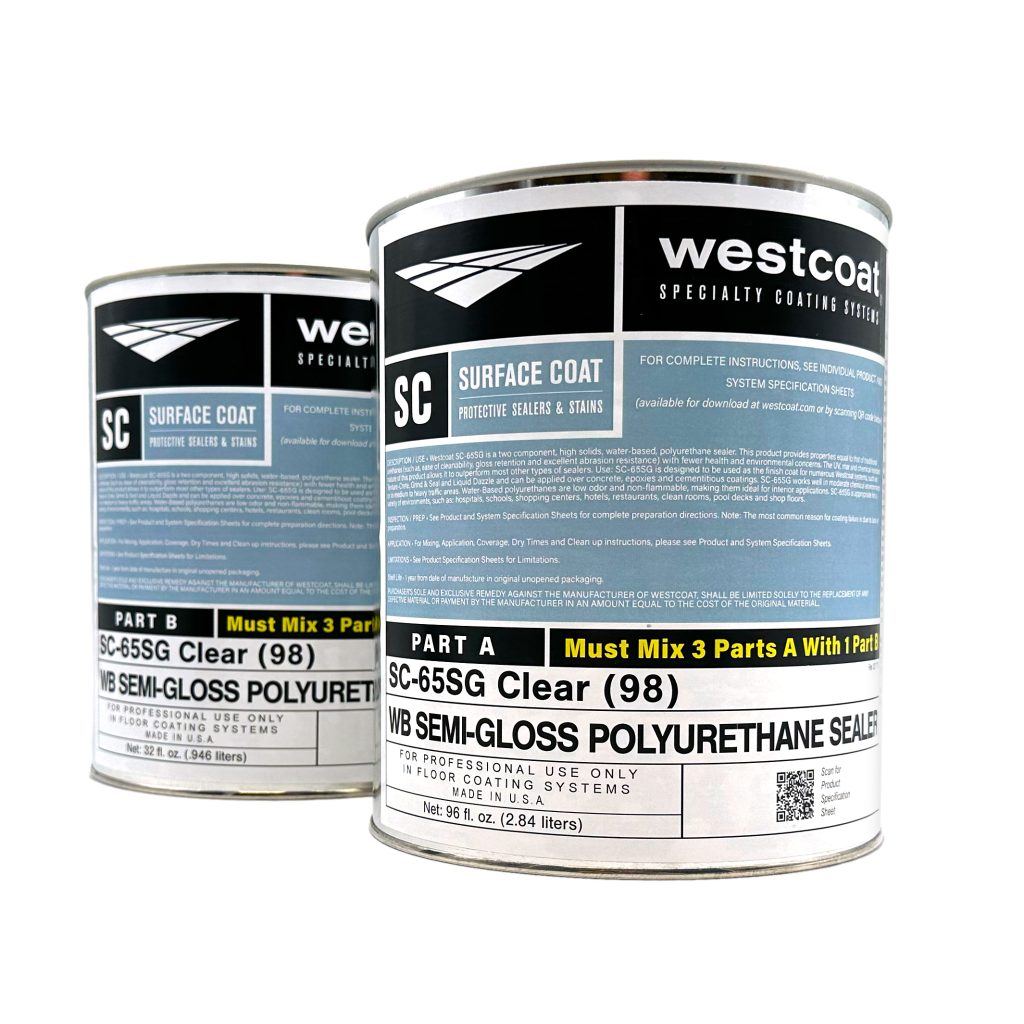

Westcoat SC-65 Water-Based Polyurethane Sealer

SC-65 enhances the color of stained concrete without yellowing and delivers top-tier abrasion and chemical resistance.

- Gloss, Semi-Gloss, or Flat

- Non-yellowing and UV-resistant

- High abrasion and chemical resistance

- Interior/exterior

- Up to 650 sq ft/gal

Westcoat EC-11 Water-Based Epoxy

EC-11 offers strong adhesion, moisture tolerance, and fast dry times for interior floors.

- Medium-gloss epoxy

- Primer or interior finish coat

- Strong chemical resistance

- Long pot life, fast dry

- 300–600 sq ft/gal

Westcoat SC-70 Acrylic Lacquer (Exterior Only)

SC-70 darkens and enriches color while delivering rapid curing for exterior slabs.

- High-gloss “wet look”

- UV-resistant

- Fast-drying

- Durable exterior resin

- 200–400 sq ft/gal

Westcoat SC-42 Water-Based Acrylic Sealer

SC-42 offers dependable protection with a semi-gloss finish.

- Semi-gloss acrylic

- Interior/exterior

- UV-resistant

- Easy application

- 250–400 sq ft/gal

Westcoat Stain and Sealer Pairing Guide

| Application | Stain Options | Sealer Options | Benefits |

|---|---|---|---|

| Residential Interior | SC-35 SC-37 | EC-11 SC-65 SC-42 | Low Odor Decorative |

| Residential Interior | SC-36 | EC-11 SC-65 SC-42 | Vibrant, Blendable Colors Ultra-Fast Drying Stain |

| Retail/Commercial | SC-36 SC-37 | SC-65 | High Durability |

| Exterior Patios | SC-35 SC-37 | SC-70 SC-42 SC-65 | UV Resistant Weather Durability |

| Driveways | SC-35 SC-37 | SC-42 SC-65 | Tire Resistance |

| Hospitality | SC-36 SC-37 | SC-65 | Chemical and Abrasion Resistant |

| Decorative Exterior | SC-35 SC-37 | SC-70 | “Wet Look“ Enhanced Color |

Westcoat Grind, Stain, and Seal Installation Overview

Below is a general summary of the installation process for a Westcoat Grind, Stain & Seal System. Because this system can incorporate multiple stains (SC-35, SC-36, SC-37) and several different sealers (EC-11, SC-42, SC-65, SC-70), application steps and product requirements may vary based on the specific combination used.

For complete installation instructions—including detailed preparation, mixing, application techniques, coverage rates, and cure-time requirements—installers must review all relevant system specification sheets and TDS documents for the selected products.

Download Westcoat Product Technical Data Sheets (TDS)

Download Westcoat System Specifications

It is the installer’s responsibility to read, understand, and follow all product specifications before beginning work.

Step 1 | Inspect and Test

- Moisture limit: ≤5 lbs MVER / ≤75% RH

- Check for contamination, repair needs

Step 2 | Mechanical Grinding

- 60 – 80 grit diamonds

- CSP-2/3 profile

Step 3 | Repairs

- TC-29 for cracks/spalls

Step 4 | Apply Stain — Product Specific

| SC-35 Water-Based Stain | SC-36 Fast Stain | SC-37 Nano Stain | |

|---|---|---|---|

| Mixing Requirements | Shake well, ready-to-use; may be diluted with water | Must be mixed with acetone per TDS ratios | Shake well, ready-to-use; may be diluted with water (up to 4:1) |

| Application Method | Sprayer, microfiber pad, or roller; thin even coats | Acetone-resistant sprayer only; avoid roller/pad | Sprayer or microfiber pad; thin coats with consistent passes |

| Key Installation Notes | Best over CSP-2/3 profile; can pre-dampen surface for softer tones; mockups recommended | Extremely rapid absorption; ideal for polished concrete and layered effects; requires precise technique; mockups recommended | Nano pigments penetrate deeply; great for variegation; multiple light coats; mockups recommended |

| Dry Time | 30–60 minutes | Seconds to minutes | 30–60 minutes |

| Safety | Low odor; water-based; minimal PPE beyond standard | HIGHLY FLAMMABLE — strict no-flame environment, full ventilation, PPE required | Low odor; water-based |

Step 5 | Apply Sealer — Product Specific

| EC-11 WB Epoxy | SC-42 WB Acrylic | SC-65 WB Polyurethane | SC-70 Acrylic Lacquer | |

|---|---|---|---|---|

| Interior or Exterior | Interior Only as a Finish Coat | Interior & Exterior | Interior & Exterior | Exterior Only |

| Application Method | Squeegee & backroll or roller | Sprayer or roller; thin coats | Squeegee or roller in thin, even coats; avoid overworking | Sprayer or roller; thin coats |

| Key Installation Notes | Long pot life; strong adhesion | Breathable; ideal for driveways, walkways; resists hot tire pickup | Excellent durability; maintain a wet edge to avoid lap lines | High-gloss wet look; fast drying; enhances color dramatically |

| Key Installation Notes | Not UV stable, must be top-coated with a pigmented sealer outdoors, like Westcoat SC-10 | SC-65 Flat CANNOT be applied directly over concrete or stained concrete, MUST be applied over EC-11 (interior) or SC-65 Semi-Gloss/Gloss (interior or exterior) |

Step 6 | Cure and Return to Service — Product Specific

| EC-11 WB Epoxy | SC-42 WB Acrylic | SC-65 WB Polyurethane | SC-70 Acrylic Lacquer | |

|---|---|---|---|---|

| Light Foot Traffic | 12-24 Hours | 4-12 Hours | 24 Hours | 1-3 Hours |

| Normal Foot Traffic | 24-48 Hours | 24 Hours | 24-48 Hours | 24 Hours |

| Vehicular/Heavy Loads | Not Recommended | 72 Hours | 72 Hours | 48-72 Hours |

| Full Cure | ~72 Hours | ~72 Hours | ~72 Hours | 24-48 Hours |

Best Practices for Successful Grind, Stain, and Seal Installations

Monitor Weather Conditions — Avoid exterior applications before expected rain (48 hours) or heavy dew (24 hours), and account for temperature and humidity during staining and sealing.

Control Surface Moisture — Always verify MVER/RH levels and ensure the slab is dry, clean, and fully absorbent before applying stains or sealers.

Achieve Consistent Surface Prep — Maintain uniform grinding (typically 60–80 grit metals, CSP-2/3) to ensure predictable stain absorption and color development.

Maintain a Wet Edge During Sealer Application — Particularly important with water-based polyurethanes like SC-65 to avoid roller marks, lap lines, or gloss variation.

Use Slip Resistance Where Needed — Incorporate Westcoat Safe Grip aggregates (CA-29, CA-30, CA-31) into the final sealer coat in wet or high-traffic areas.

Box Stain Batches for Color Consistency — Combine multiple batches of SC-35, SC-36, or SC-37 to ensure uniform color across large or highly visible areas.

Mask, Protect, and Maintain Ventilation — Keep edges, adjacent finishes, and vertical surfaces clean, and maintain proper airflow for safe, uniform curing—especially with fast-drying stains like SC-36.

Why Specify a Westcoat Grind, Stain, and Seal System?

A Westcoat Grind, Stain & Seal system delivers a balanced combination of decorative flexibility and long-term durability for both interior and exterior concrete surfaces. By pairing proven stain technologies (SC-35, SC-36, SC-37) with high-performance sealers (SC-65, EC-11, SC-70, SC-42), the system offers:

- Reliable adhesion and predictable performance on properly prepared concrete

- Exceptional color versatility, from subtle natural tones to bold, high-intensity finishes

- UV-stable protection and weather durability when specified with the appropriate sealer

- Low-odor, VOC-compliant options suitable for occupied or sensitive spaces

- Straightforward maintenance with long-term cost efficiency

This blend of aesthetic customization, protective performance, and installer-friendly chemistry makes Westcoat’s Grind, Stain & Seal systems a trusted choice for contractors seeking reliable, professional-grade results.

Ready to Upgrade Your Next Project?

Shop the full Westcoat Grind, Stain & Seal system at Concrete Exchange — everything you need for durable, decorative, and easy-to-maintain concrete finishes in one place.

- SC-35 Water-Based Stain

- SC-36 Fast Stain

- SC-37 Nano Stain

- EC-11 Water-Based Epoxy

- SC-42 Water-Based Acrylic Sealer

- SC-65 Water-Based Polyurethane Sealer

- SC-70 Acrylic Lacquer Sealer

- Safe Grip Aggregates (CA-29, CA-30, CA-31) for optional slip resistance

Precision Matters in Grind, Stain, and Seal Systems

For professional contractors, system success depends on selecting the right stain chemistry, sealer technology, and surface preparation methods. With SC-35, SC-36, and SC-37, installers have flexible color systems for any project. When paired with proven sealers like SC-65, EC-11, SC-70, and SC-42, the Grind, Stain, and Seal systems deliver consistent, long-lasting performance in residential, commercial, and exterior environments.

Concrete Exchange offers system recommendations, project support, and technical expertise to help contractors execute every installation with confidence.

Need Help Choosing the Right System?

Not sure which stain or sealer combination is best for your project? Our team at Concrete Exchange is here to help.

Book a free 20-minute consultation, and we’ll walk you through the ideal products for your concrete surface, environment, traffic level, and desired finish.

Whether you’re sealing a residential floor, upgrading a commercial space, or tackling an exterior project, we’ll help you select a professional-grade Grind, Stain, and Seal system that delivers long-lasting performance and the exact look you want.

Westcoat TDS and System Specifications

| Download Westcoat System Specifications | Products Used in Spec Sheet |

|---|---|

| Interior Water-Based Stain Grind & Seal | SC-35 Stain with EC-11 Epoxy; Optional SC-65 Topcoat for Greater Durability |

| Interior Fast Stain Grind & Seal | SC-36 Stain with EC-11 Epoxy; Optional SC-65 Topcoat for Greater Durability |

| Interior or Exterior Nano Stain Grind & Seal | SC-37 Stain with SC-65 Sealer |