Recycled Container Concrete Planter

This Guide will explain how to make concrete cylinders using discarded cardboard packaging tubes (potato chips, ground coffee, mixed nuts, baby formula, etc.)

These tubes were found in recycling bins at a nearby apartment complex. It might take a few trips to find the right sizes, but keep looking, because they’re being thrown away all the time.

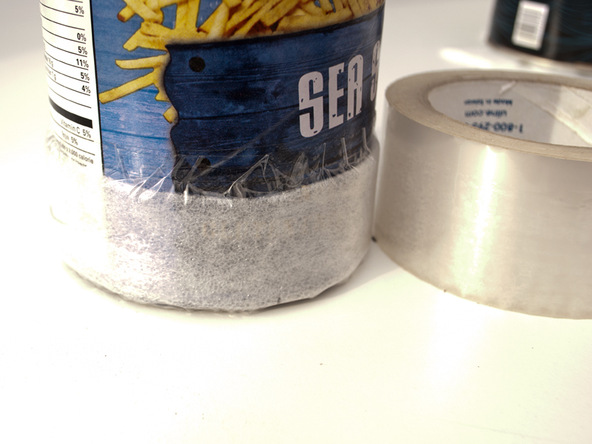

The largest tube will become the outside form. In this case it’s about 5″ diameter and 9″ tall (it contained coffee grounds). The inside tube is about 4″ x 7″ (shredded potato chip container). This means the wall thickness is only about 1/2″. Do not go any thinner – this is already pushing the limits.

What You’ll Need

- Permanent Marker

- Tin Snips/Wire Cutters

- Long Needle-Nose Pliers

- Phillips Screwdriver

- Scissors

- Weights/Rocks/Sand

- Alpha Diamond Hand Polishing Pads (Set of 7)

- Particle Mask

- Rubber Gloves

- Cardboard Tubes (with foil or plastic lining) (2)

- 1″ Drywall Screws (4)

- Clear Packing Tape

- Thin Foam Wrap

- Sacked Concrete Mix

- CHENG Outdoor Pro-Formula