Fabric Formed Concrete Fire Table

THREE: SPRAYING AND BACKING

A face coat of D-FRC Casting Blend is sprayed into the form, and then a backer mix is laid up by hand, at 1-1/2″ thick, to create a strong yet relatively lightweight fire table.

Step 1 – Mixing D-FRC Casting Blend

Step 2 – Spraying

Step 3 – Cutting the Casting Blend with Basalt Fiber to Create the Structural Backer

Step 4 – Backing

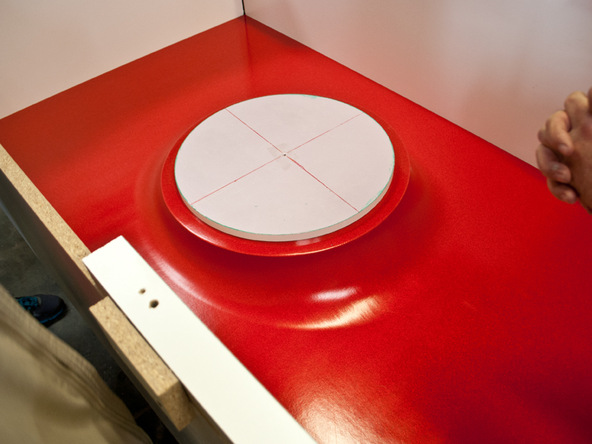

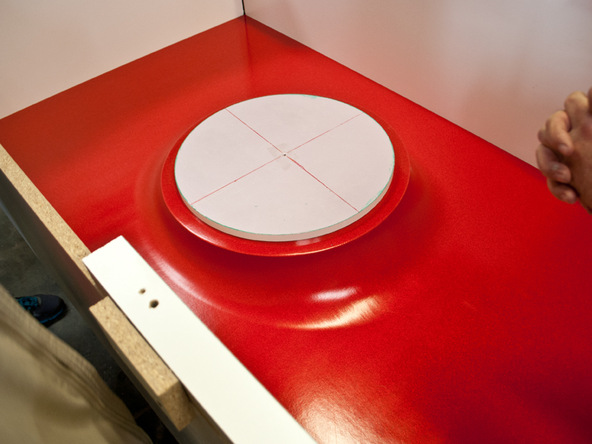

Previous: Vacuum Hookup

A shop vac is attached to the form base during casting to provide suction that pulls the vinyl fabric into graceful curves around the rigid foam risers.

Next: Demolding

After the piece has cured for 12-24 hours, it can be removed from the formwork. Before demolding, the project is ground flat on the bottom edge.