Recycled Glass Countertops

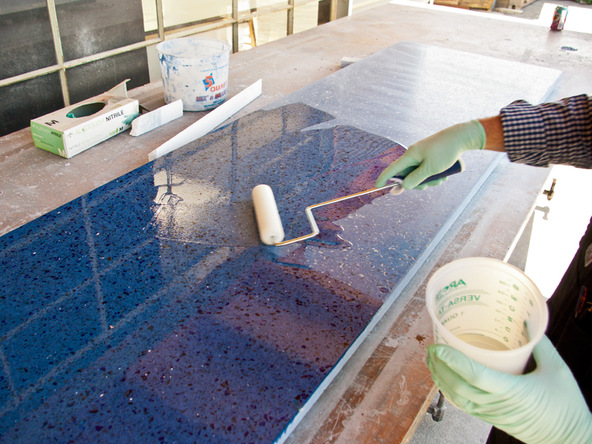

SEVEN: SEALING

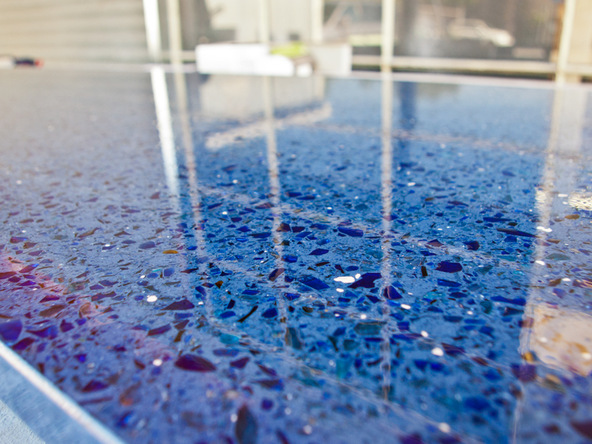

To achieve the boldest color possible, we are going to seal this recycled glass countertop section with a high-gloss color-enhancing sealer. We’ll apply two coats of Surecrete PC12 Sealer, which will provide adequate protection and performance.

If this were a kitchen or bath project, we’d likely sand and seal an additional two coats to create a higher quality finish.

What You’ll Need

- Surecrete XS-PC12 Sealer

- 6″ Foam Roller Cover

- 6″ Paint Roller

- Graduated Mixing Container – Quart

- Stir Stick

- Rubber Gloves

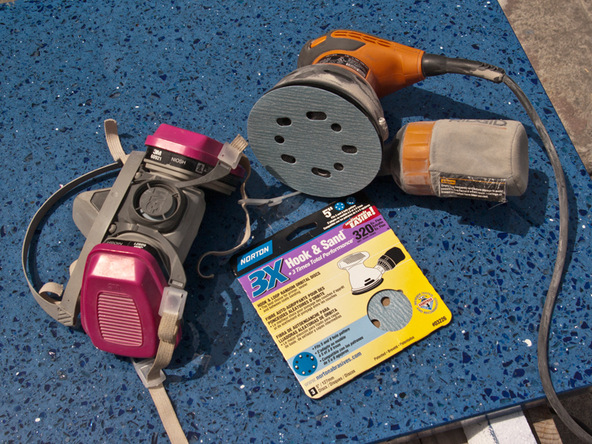

- Orbital Sander

- 320-Grit Sandpaper

- Particle Mask

Step 1 – Supplies

Step 2 – Mix and Stir Sealer

Step 3 – Apply Sealer

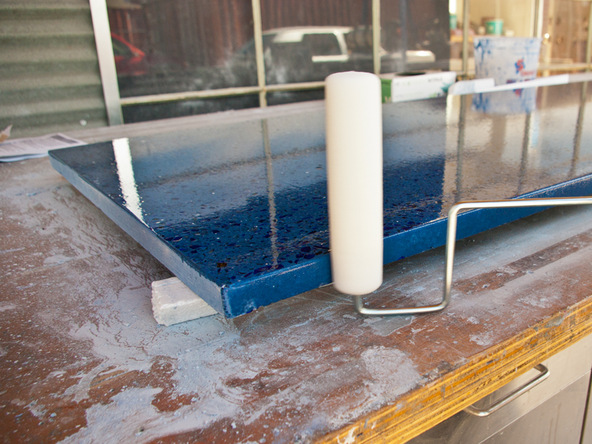

Step 4 – Backroll

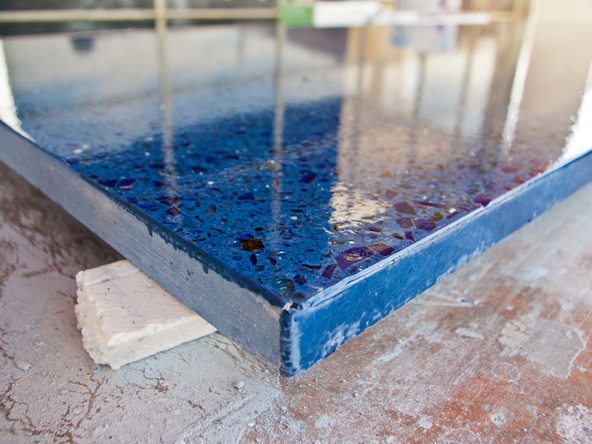

Step 5 – Roll Edges

Step 6 – Cure Sealer

Step 7 – Sand Sealer

Step 8 – Sand

Step 9 – Wipe

Step 10 – Apply Second Coat of Sealer

Step 11 – Cure and Final Polish

Previous: Polishing

For this project we chose to use a single head wet/dry polisher, but if this project were any bigger, we’d have used a triple-head planetary polisher.