A big THANK YOU to everyone who attended the concrete countertop forming demo this morning in our newly renovated warehouse at 1036 Grayson Street, Berkeley, CA. It was fun to have so many good folks to share our love of concrete countertops with, and we can’t wait to see you next weekend for the concrete casting demonstration. Space is still available, it’s free, so if you’d like to join us register here.

Share This Post

For those who couldn’t make it to this morning’s session, we’ve pulled together a few photographs and videos from the class so you can follow along. Over the next few weeks we’ll build a concrete countertop from template to installation using many of the innovative concrete countertop products available at CHENG Concrete Exchange. In this demonstration we spent a lot of our time working with CHENG Concrete Countertop Forms, Edge Form Liners, and Glossy Form Tape.

A Precise Countertop Template Ensures That Your Installation Will Fit Perfectly

A Precise Countertop Template Ensures That Your Installation Will Fit Perfectly

Clay Lai started the session by templating a 6′ run of cabinet bases set-up in our warehouse. The template for this countertop was constructed by hot-gluing together 3″ wide strips of luan plywood – our favorite template making method because you can get in and out of a job-site with out making a mess.

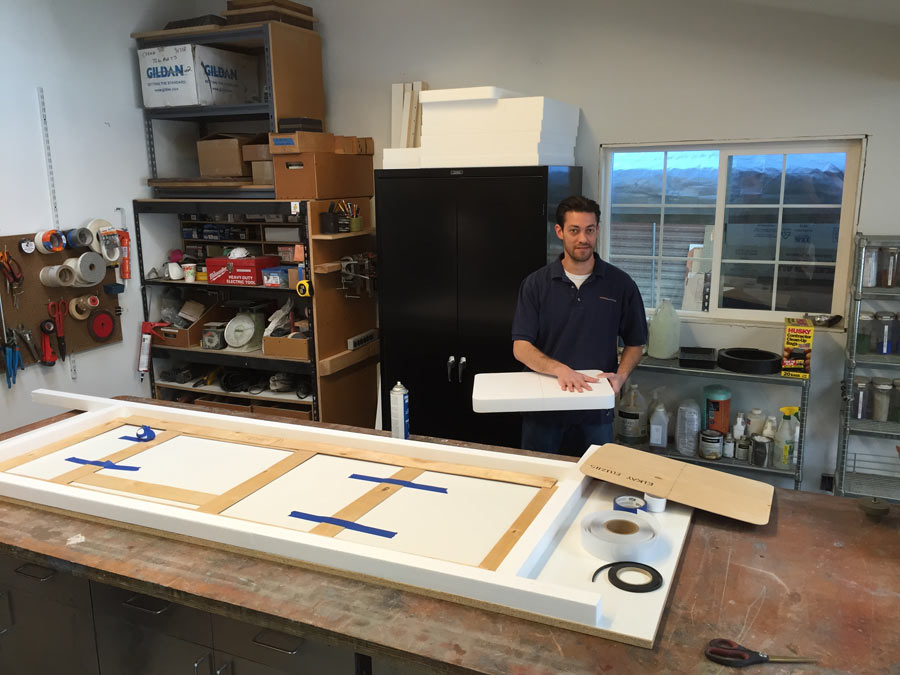

A Well Organized Workshop Makes Everything Run Smoothly

A Well Organized Workshop Makes Everything Run Smoothly

After the template is completed, we adhere it to a 3/4″ thick base-form made of melamine coated particle board. Melamine is a great mold making material because it’s pre-sealed with a plastic coating that prevents concrete from sticking to the form and leaves a very subtle texture that can be easily polished away with diamond polishing pads.

Foam-Lok Spray Adhesive is the Secret to Forming a Job in Minutes

Foam-Lok Spray Adhesive is the Secret to Forming a Job in Minutes

CHENG Concrete Countertop Forms are a snap to place when you use Foam-lok Spray Adhesive to set them. With the template secured to the base-form, simply spray a generous amount of adhesive around the entire perimeter of the template before placing the concrete countertop form sections in place.

Only use adhesives that are specifically formulated for use on EPS foam. Most adhesives contain harsh solvents that will dissolve or melt EPS.

A subtle but important detail of the video clip above is how Clay used the template as masking to prevent overspray from landing on the form-base. Using this mold-making method allows you to rail up an entire concrete countertop project in minutes without creating tremendous waste or lengthy clean-up times.

2 Pound EPS Foam is Easily Shaped With Sand Paper, Sharp Saws, and Routers

2 Pound EPS Foam is Easily Shaped With Sand Paper, Sharp Saws, and Routers

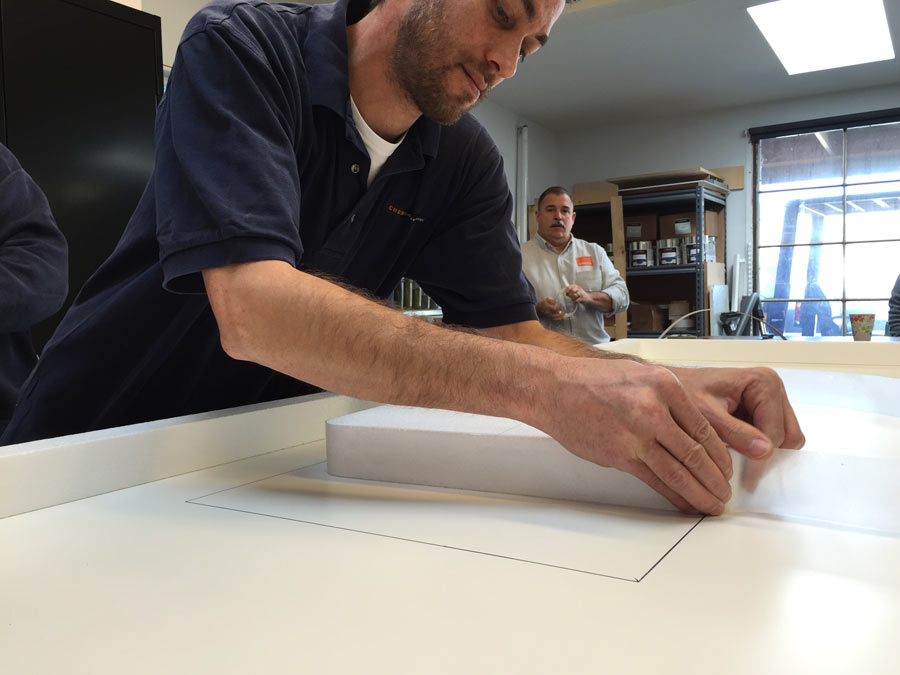

A 2″ block of foam is used to create an under-mount sink knockout to the exact size and shape of the Elkay sink we’ve chosen for our kitchen concrete countertop. Before we can place the sink knockout into our form the sides are faced with Glossy Form Tape to produce a glossy smooth finish on the inside of our finished under-mount sink opening.

CHENG Glossy Form Tape Has Many Uses – This is One

CHENG Glossy Form Tape Has Many Uses – This is One

Wrap the Glossy Form Tape around the sink knockout by placing both the sink knock-out and the glossy form tape on a flat surface before wrapping the foam to ensure the tape doesn’t “ride” up the edges on an angle. We took some time at this point in the demonstration to talk about the new sizes of CHENG Glossy Form Tape, now available in 1″, 1-1/2″, 2″, and 2-1/2″.

CHENG Edge Form Liners are an Inexpensive Way to Get Satin Smooth Countertop Edges

CHENG Edge Form Liners are an Inexpensive Way to Get Satin Smooth Countertop Edges

Before placing the sink knock-out, Clay cut to length and adhered the CHENG Edge Form Liners to the CHENG Countertop Forms using Foam-lok Spray Adhesive. The form liners will give the edges of our concrete countertop a satin smooth finish in lieu of the rough texture of the concrete countertop forms.

Shape Silicone with Style using CHENG Silicone Edge and Seam Shaping Tools

Shape Silicone with Style using CHENG Silicone Edge and Seam Shaping Tools

Next it was time to seal the entire concrete countertop form with silicone sealant. Doing this serves too prevent concrete slurry from flowing between the form parts and potentially prying the forms apart. While the silicone sealant is still malleable we use Silicone Edge and Seam Shaping Tools to create graceful eased edges and corners to minimizes the amount of time we’d spend shaping and polishing rough edges on our finished concrete countertop.

Demonstrating how to use the Silicone Edge and Seam Shaping Tools is always a high point of any training session. It’s pretty amazing how precise and smooth you can shape silicone with nothing more than a steady hand, razor blades, and hand-polished acrylic shaping rods.

This is where we wrapped up today’s demonstration, but we will resume this concrete countertop project next Saturday morning. If you’re in the San Francisco bay area, we’d love to have you join us for the next phase of this project when we’ll finish the mold, add reinforcing, mix, cast, and vibrate this concrete countertop. We’ll also add some decorative stones, aggregates, stainless trivet knock-outs, and talk about concrete colors. Space is still available, it’s free, so if you’d like to join us register here.

If you’re interested in learning more about concrete countertop casting, consider attending our 3-Day Comprehensive Concrete Countertop Class hosted by the California Living Museum in Bakersfield, CA. This special training event will cover many popular casting methods with each being installed at the Living Museums Zoo. For more details visit the training details webpage here.

Share This Post